Add to Cart

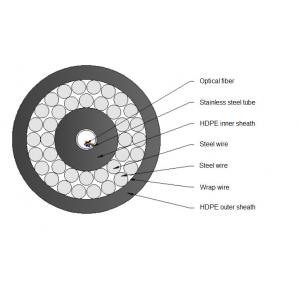

DA- Double Steel Wires Armored Submarine Optical Cable-160KN

Dawnergy’s double steel wires armored submarine optical cable’ single-mode/multimode fibers are housed in a tube that is made of stainless steel and filled with tube filling compound. Steel wires is wrapped outside the HDPE inner sheath. Finally, a HDPE outer sheath is extruded.

Fiber Optic Characteristics-G652D

| Item | Contents | Value | |

| Before cable | After cable | ||

| Attenuation | @1310nm | ≤0.35dB/km | ≤0.38dB/km |

| @1383nm | ≤0.34dB/km | ≤0.36dB/km | |

| @1550nm | ≤0.21dB/km | ≤0.22dB/km | |

| @1625nm | ≤0.24dB/km | ≤0.28dB/km | |

| Dispersion | @1288nm~1339nm | ≤3.5ps/(nm·km) | |

| @1550nm | ≤18ps/(nm·km) | ||

| @1625nm | ≤22ps/(nm·km) | ||

| Zero-Dispersion wavelength | 1300nm~1324nm | ||

| Zero-Dispersion slope | ≤0.092ps/(nm2·km) | ||

|

Mode field diameter (MFD) |

@1310nm | 9.2±0.4μm | |

| @1550nm | 10.4±0.8μm | ||

| Cable cutoff wavelength λcc(nm) | ≤1260nm | ||

|

Micro bending Attenuation |

@1550nm (1turns; Φ32mm) | ≤0.05dB | |

| @1550nm (100turns; Φ60mm) | ≤0.05dB | ||

| Link polarization dispersion (PMDQ) | ≤0.15ps/km1/2 | ||

| Geometrical characteristics | |||

| Cladding diameter | 125±1.0μm | ||

| Cladding non-circularity | ≤1% | ||

| Core/cladding concentricity error | ≤0.6μm | ||

| Fiber diameter with coating (uncolored) | 245±7μm | ||

| Cladding/coating concentricity error | ≤12.0μm | ||

| Mechanical characteristics | |||

| Proof stress | ≥0.69GPa | ||

| Fiber curl | ≥4m | ||

| Coating strip force | 1.0~8.9N | ||

| Environmental characteristics | |||

| Temperature induced attenuation (-60~+85℃) | ≤0.05dB/km | ||

| Dry heat induced attenuation (85℃±2℃, 30 days) | ≤0.05dB/km | ||

| Water immersion induced attenuation (23℃±2℃, 30 days) | ≤0.05dB/km | ||

|

Damp heat induced attenuation (85℃±2℃, RH85%, 30 days) |

≤0.05dB/km | ||